Support that goes

the distance

Beyond launch

Spare parts

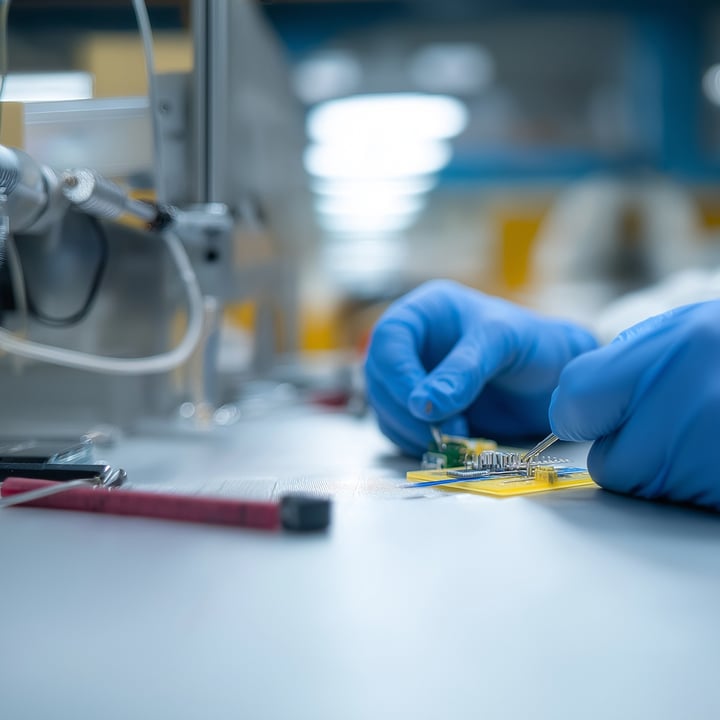

Spare parts support that powers performance, protects compliance, and keeps your solutions running strong.

When your solution is used in a healthcare setting, the last thing anyone needs is downtime. That’s why HiArc’s spare parts management support service is engineered for speed, reliability, and product longevity. We provide ongoing availability of high-quality components from approved vendors, with every detail aligned to the unique configurations and lifecycle plans of your instrument.

Backed by decades of experience supporting regulated environments, we anticipate what’s needed to keep you running smoothly - and help avoid costly interruptions. Whether it’s a legacy design or a new platform, we manage parts support with the same attention to quality and compliance that shapes our engineering process. You get more than a parts catalog. You get a partner who knows your system inside and out.

HiArc’s spare parts services are rooted in real-world experience supporting complex clinical equipment. From mechanical subassemblies to electronics and consumables, we help ensure continuity of supply for critical components—long after launch. Our teams coordinate with design and manufacturing leads to ensure fit, function, and compliance are preserved across changes in supply or obsolescence.

Where needed, we also advise on inventory planning and part replacement strategies that reflect usage patterns and product volumes. For regulated systems, we understand the impact of part changes on documentation and validation, and we work to help you stay ahead of any disruptions.

It’s about protecting your product’s integrity, your brand’s reputation, and your clients’ trust - one component at a time.

Don’t wait for downtime—stay prepared

Refurbishment

Extend system life, restore function, and retain compliance with ISO-aligned refurbishment services.

HiArc’s refurbishment services help clients extend the useful life of their installed systems - preserving field performance while minimizing disruption and cost. Our teams assess returned components or instruments and apply rigorous processes to restore functionality and ensure compliance with applicable standards.

It’s not just about fixing what’s broken. It’s about maintaining trust in every unit in the field. For OEMs and system owners, this means fewer field failures, more predictable service lifecycles, and support that exceeds your quality and regulatory expectations.

Backed by decades of experience supporting regulated environments, we anticipate what’s needed to keep you running smoothly - and help avoid costly interruptions. Whether it’s a legacy design or a new platform, we manage parts support with the same attention to quality and compliance that shapes our engineering process. You get more than a parts catalog. You get a partner who knows your system inside and out.

Our refurbishment work is underpinned by the same quality ethos that guides production. Using ISO 13485 certified procedures, we manage teardown, inspection, replacement, and revalidation - ensuring each returned unit can be confidently placed back in service.

HiArc teams communicate closely with clients to define success criteria and turnaround expectations. Whether the challenge is wear over time, unexpected damage, or a broader fleet refresh, we bring structure and consistency to every refurbishment process. You stay in control. Your system stays field-ready.

Get more from what you’ve already built

Obsolescence management

Proactive obsolescence planning that protects performance, regulatory integrity, and long-term clinical continuity.

HiArc helps clients stay ahead of obsolescence by monitoring at-risk components and aligning early on transition strategies. Our engineering and supply chain teams work together to mitigate disruption - evaluating alternatives, updating documentation, and validating changes that maintain system integrity.

We don’t just react - we anticipate. And we understand what’s at stake when a small upstream change risks broader system qualification or regulatory status. That’s why our obsolescence support is built into our lifecycle view, not bolted on as an afterthought.

At HiArc, obsolescence management is a proactive discipline - deeply integrated into how we support clinical systems over time. We continuously track at-risk components and forecast supply constraints to prevent last-minute disruptions. When risks emerge, we act early: validating alternates, managing documentation, and coordinating regulatory impact assessments.

Our engineers, supply chain experts, and quality teams work as one to ensure that even necessary changes don’t compromise system performance or compliance. It’s not just about staying ahead - it’s about staying aligned with your goals, your roadmap, and your obligations to clinicians and regulators.

Prevent problems before they start

Compliance monitoring

Ongoing surveillance and guidance to help you stay audit-ready and regulator-aligned, year after year.

When regulations shift, your system must respond. HiArc’s post-market support helps ensure ongoing compliance through surveillance of applicable standards and change impact assessment. From ISO 13485 to FDA QSR parts 820, 803, and 806, we monitor developments that could affect your instrument and advise on how to act.

It’s compliance support that helps you avoid costly delays, rushed updates, and missed opportunities. And it’s backed by the same regulatory fluency that shaped your system in development.

In regulated industries, compliance isn’t a checkbox, it’s a moving target. At HiArc, we integrate regulatory surveillance and compliance monitoring into your development process to help you anticipate change, avoid delays, and move forward with confidence.

Our teams track evolving standards and guidance, from FDA requirements to ISO updates, and translate them into practical strategies that keep your program aligned and inspection-ready.

Whether we’re supporting design documentation, risk management, or early-phase validation, our goal is the same: keep your launch on track and your product future-proof.

With HiArc, you don’t just meet compliance. You stay ahead of it.

Stay ahead of what’s next

Support that starts long before launch

Our service model is informed by the entire product lifecycle. That’s why support is connected to the teams who designed, built, and tested your system.

Quality isn’t a step—it’s how we think, build, and deliver the future of healthcare.

Suneet Chadha, President, HiArc

Engineering grounded in quality

Our engineering work is backed by ISO 13485-certified systems, FDA-compliant processes, and decades of experience designing diagnostics that perform under pressure.

Expertise that meets you where your market is

From regulatory strategy to technical integration, HiArc brings cross-functional expertise that flexes to your team, goals, and stage of development.