Manufacturing aligned from the start

From prototype to product confidence

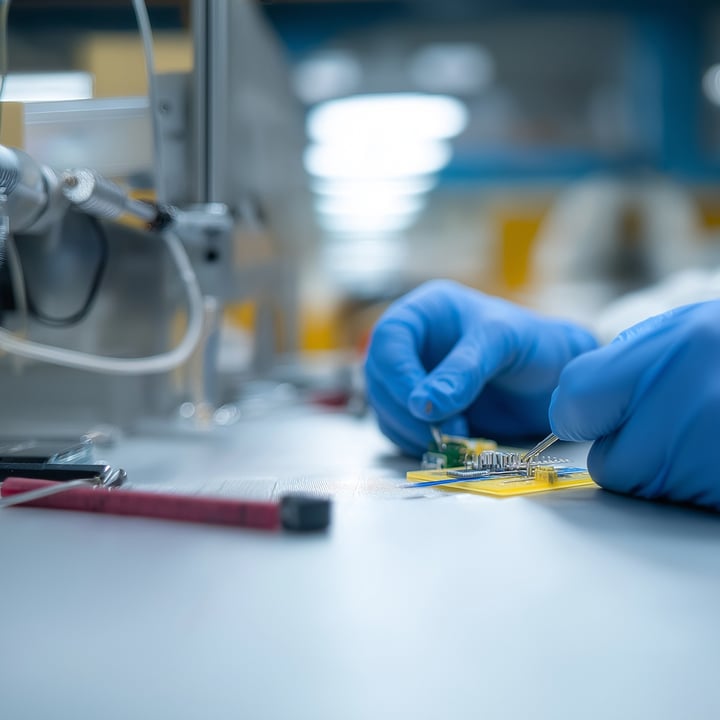

System level production

System integration and readiness - aligned with ISO 13485 processes for compliant clinical product delivery.

HiArc has a long track record of delivering high-value production-ready clinical systems that meet stringent controls for performance, compliance, and quality. From subassembly coordination to full system integration, we help ensure designs are assembled, verified, and ready to perform.

What sets our approach apart is how closely production aligns with upstream engineering. You benefit from designs that were developed with manufacturability in mind - and from teams that stay engaged right through delivery. Whether executed in-house or through trusted partners, your build is managed with the same precision that defines our design process. The result: a system that’s not just assembled, but smarter and built to deliver - day one, real world.

When it’s time to move from design into the realities of production, HiArc is ready for the critical transition—those first 12 to 18 months post-launch, where engineering meets execution. This is the high-stakes phase of new product introduction: where initial builds, regulatory readiness, and quality systems are tested in real time. It’s not about full-scale, steady-state manufacturing. It’s about getting your product to market—and getting it right—faster, smarter, and with fewer surprises.

We bring Design for Excellence (DFX) thinking and deep NPI expertise to every project, helping ensure your system is not just manufacturable, but truly launch-ready. With HiArc, your initial builds deliver the performance, precision, and compliance your market expects—on day one.

And because our engineering and manufacturing are fully integrated, your design intent stays intact. No handoffs. No guesswork. No disconnects between prototype and production.

ISO 13485-certified and FDA QSR-aligned (Parts 820, 803, 806), our processes give you the confidence and traceability you need when every unit counts—and when every decision in these first builds sets the tone for future success.

Move from prototype to production

Global supply chain management

Program-specific supplier oversight with global reach, quality alignment, and rigorous approval processes built in.

At HiArc, we’ve managed global supply chains through changing regulations, shifting timelines, and serious complexity. We know how to keep the parts moving, the paperwork clean, and the risks low.

We know your components don’t just need to arrive - they need to arrive right, on time, and fully traceable. HiArc’s supply chain team works across quality and engineering functions to manage vendor qualification, documentation, and change control - all aligned to ISO 13485 and FDA QSR.

The result? Fewer compliance gaps, faster changes, and smoother handoffs - because supply and quality are always in sync. What’s more, our supply chain isn’t siloed - it’s connected to your system design, compliance strategy, and delivery goals from the start. With trusted and approved vendors we help build a supply chain that’s reliable, timely, auditable, and ready to support your product’s next move.

HiArc’s team sources mechanical, electrical, and custom components from a global network of vetted suppliers. We manage approved vendor lists, traceability requirements, and material flows as part of an integrated quality system that meets ISO 13485 and FDA QSR standards.

Our team brings stability to complexity - tracking approved vendors, managing changes with control, and ensuring delivery without disruption. It’s a disciplined process, built for the realities of regulated environments.

Make supply chains work for you

Value and sustaining engineering

Extend your product’s life, manage change, and reduce cost - without compromising quality or compliance.

At HiArc, we believe early is everything. That’s why our pre-launch value engineering services are designed to help you refine your product before it hits production. From cost efficiencies to manufacturability enhancements, we work with you to optimize design while protecting performance and compliance.

This is more than just fine-tuning. It’s smart, structured engineering—built into the NPI phase—to reduce complexity, streamline assembly, and get your product ready for the realities of production. Whether it’s simplifying components or eliminating unnecessary cost, we help you make confident decisions that last.

Because when you’re building something that matters, how you start makes all the difference.

Success at launch starts with smarter design decisions. HiArc’s Design for Excellence (DFX) and Value Engineering (VAVE) services help you optimize cost, quality, and manufacturability—right from the start.

We integrate these capabilities during design and NPI phases to eliminate waste, simplify assembly, and drive performance without trade-offs. It’s not about reacting to issues post-launch—it’s about building a better product before it ever leaves the line.

From material alternatives to design simplification and process efficiency, we work alongside your team to improve outcomes and reduce risk. The result? Products that are leaner, more scalable, and ready to perform in the real world—without surprises.

Our teams collaborate across engineering, quality, and supply chain to ensure updates stay aligned and fully documented. We’ve helped clients extend product lifecycles, address supply chain volatility, and capture real cost savings - without cutting corners or creating new risks. The value isn’t just in what gets fixed. It’s in what stays strong, scalable, and compliant as your platform evolves.

Optimize early, launch smarter

MES and QMS integration

HiArc’s refined MES and QMS systems work in tandem to ensure traceability, compliance, and control at every step.

At HiArc, our ISO 13485-certified production approach is built into every step, with FDA QSR Part II compliance and cGMP alignment, and quality standards that match the demands of regulated markets. We've delivered complex, compliant systems into the real world, and we understand what it takes to meet quality expectations under pressure.

Whether working directly on production or overseeing trusted partners, we maintain the same level of oversight and documentation rigour. Our teams stay closely aligned with your compliance strategy and your product’s intended use. The result? Quality that doesn’t have to be retrofitted - it’s already there.

ISO 13485 certified production means traceability, documentation, and risk control aren’t bolted on - they’re built in. At HiArc, we help ensure compliance is embedded in your processes from the start, so you’re not chasing quality later.

We work with your internal teams and external partners to define documentation flows, align quality checkpoints, and support the validation paths that matter most in regulated production. From test protocols to traceable parts, every compliance-critical detail is considered early - and captured clearly.

Because our approach integrates design, manufacturing, and quality from day one, you move through audits, tech transfer, and launch with fewer unknowns and more control. In regulated clinical environments, that’s not a nice-to-have - it’s non-negotiable.

Discover how deep quality runs at HiArc

ISO13485 certified production

Our ISO 13485 certified processes build in traceability, audit readiness, and real-world product confidence, from the start.

Since 1980, we’ve helped bring complex clinical platforms into production with quality systems and infrastructure refined over decades. Our Manufacturing Execution System (MES) FactoryLogix, tracks and controls production in real time, capturing data at every step to ensure timing, traceability, and consistency.

It connects seamlessly with our Product Lifecycle Management (PLM) system, TeamCenter, and Enterprise Resource Planning (ERP) system, Oracle, bridging planning, design, and factory-floor execution.

Every data point from the line feeds directly into our Quality Management System (QMS) - certified to ISO 13485 and aligned with FDA QSR - so what happens on the line is reflected in documentation, inspections, and release controls. Together, these systems form an integrated framework that connects execution with compliance, and quality with delivery confidence.

HiArc’s MES and QMS aren’t just systems - they’re embedded in how our teams think and work. From skilled assemblers to regulatory experts, every team member is committed to executing their part within tightly controlled processes that preserve compliance and accelerate delivery.

Because we’ve lived these systems for decades, we don’t just track what happens - we make it meaningful. Every critical result is documented. Every deviation flagged. Every key step validated. And with electronic Device History Records (eDHR) fully integrated, your production records are complete, transparent, and inspection-ready - a key advantage for your regulatory path and audit confidence.

This is quality that goes beyond surface checks - our MES and QMS systems are built deep into your process from the start. Whether we're supporting full-system builds or collaborating with your partners, we keep your operations coherent, your data inspection-ready, and your product confidently on track - at every stage of its lifecycle.

Stay ahead of every requirement

Built to scale—but it starts upstream

Reliable production begins with aligned design. Our concept and engineering teams work closely with manufacturing to deliver faster, smarter, and with fewer surprises.

Quality isn’t a step—it’s how we think, build, and deliver the future of healthcare.

Suneet Chadha, President, HiArc

100% compliant. Always accountable.

Our ISO 13485-certified manufacturing system supports FDA-regulated devices with full traceability, robust controls, and audit-ready performance at scale.

Expertise that meets you where your market is

From regulatory strategy to technical integration, HiArc brings cross-functional expertise that flexes to your team, goals, and stage of development.