Concept development, reimagined

From vision to validation

Feasibility

Early-stage clarity that tests your concept against real-world risks, constraints, and technical viability.

At HiArc, feasibility isn’t a box to tick - it’s a vital phase where we bring structure to potential. We evaluate your concept’s technical and real world viability early, so you're not guessing later. Our teams look at performance requirements, system constraints, and risk factors to determine what’s possible, what’s practical, and what’s worth pursuing.

Because HiArc works end-to-end, our feasibility studies are tightly connected with downstream engineering and manufacturing. That means the recommendations we make are grounded in real-world execution, not theory. We collaborate early, ask the right questions, and move quickly to give you a sharper view of your product’s path forward - for fewer surprises and more momentum.

HiArc’s feasibility process focuses on clarity and action. We work with your team to understand use cases, define high-level requirements, and evaluate early risks and constraints. We use product simulation and concept modeling to assess technical performance against goals like throughput, accuracy, footprint, and cost. These insights feed directly into system architecture decisions and project planning.

Because our feasibility work is integrated with broader systems - mechanical, engineering, and software design teams, we don’t lose time - or context - when it’s time to move forward. You get feasibility grounded in experience, backed by simulation, and aligned with delivery from day one.

Let’s turn feasibility into action

Requirements

We define essential project prerequisites early - to accelerate your development and reduce your risk.

At HiArc, getting the requirements right isn’t just good process - it’s fundamental to getting the product right. That’s why we bring discipline, speed, and collaboration to this early stage, helping you translate ideas into structured, prioritized and actionable design inputs.

We engage early to align on what the system must do, how it should perform, and what success looks like. Our teams draw on decades of product development experience to ask the right questions, spot potential conflicts, and anticipate downstream impact, covering requirements that are technical, financial, regulatory, resource, compliance and risk assessment based. And because we work across the full product lifecycle, we don’t define requirements in isolation - we shape them with real-world delivery in mind. The result? A smarter starting point, for accelerated, streamlined development.

HiArc’s requirements definition process is tightly linked to feasibility, simulation, and engineering design. We start by capturing high-level system goals and user needs, then translate them into clear, prioritized technical requirements. These form the foundation for system architecture, risk assessment, and design controls.

We focus on clarity, traceability, and forward momentum. Every requirement is built to deliver against regulatory and compliance needs, usability, and long-term maintainability. And because we collaborate across systems, software, electrical, and mechanical teams from day one, the transition from requirement to reality happens faster - with fewer gaps, fewer surprises, and more confidence.

Define requirements that deliver

Risk management

We define essential project prerequisites early - to accelerate your development and reduce your risk.

We treat risk management as a tool for momentum, not a checklist for compliance. It’s built into every decision from day one - because identifying risk early means problems are solved before they can slow you down. We work closely with your team to uncover potential technical, regulatory, compliance, and operational risks during concept development, so we can shape smarter solutions from the start.

Our approach is uniquely integrated. Risk isn’t offloaded to one function or buried in documentation - it’s shared across engineering, program management, and quality. By surfacing risks early and addressing them collaboratively, we reduce uncertainty, align faster, and keep development on track.

Our concept-phase risk management starts with identifying known and potential failure modes, system-level constraints, and design sensitivities. These are assessed in parallel with feasibility studies and simulation work, allowing risks to be mapped against technical decisions and requirements as they evolve.

HiArc teams continuously revisit and refine risk factors as concepts take shape - capturing them in a way that informs downstream design, not just satisfies documentation. Because our process is linked across engineering, manufacturing and quality and regulatory compliance functions, risk stays visible and actionable as development progresses. The result: fewer unknowns, faster pivots, and a product that’s better prepared for what’s ahead.

Spot blind spots early on

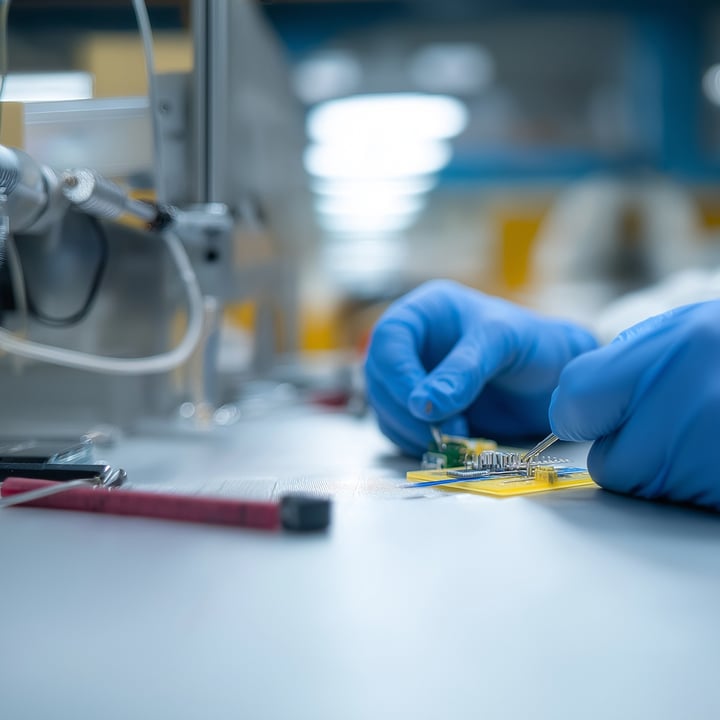

Product simulation

We integrate simulation early and regularly - cutting risk, shaping smarter requirements, ensuring compliance, and accelerating great decisions.

Simulation is where great ideas meet real-world constraints - without the time and cost of full-scale builds. At HiArc, we use product simulation early in concept development to model system behaviour, explore options, and flag issues before they slow you down, or cost you money. It’s a smarter way to make big decisions with better information, so you get to market faster.

What sets our simulation approach apart is how closely it’s tied to feasibility, risk, and requirements. We don’t just model in isolation - we connect simulation to the broader context of your system goals. That way, early insights don’t just predict performance - they shape it. For teams building complex diagnostic and life science systems, this alignment saves time, reduces rework, and builds confidence in what comes next.

HiArc’s simulation work helps answer early-stage questions about system dynamics, performance limits, thermal behaviour, and spatial configuration. We use it to evaluate how components might interact, where tradeoffs emerge, and how requirements should be refined. These insights feed directly into architecture planning and risk management, giving your team data to move forward with purpose.

Because simulation is an interactive and continuous process it’s seamlessly integrated into all stages of the process from early concept to final delivery. The result? - reduced risks, improved quality, and enhanced success of your new product.

Let’s bring your ideas to life

From concept to completion, stay with the team that delivers

Once your concept is clear, we’re ready to take it further. HiArc offers full-spectrum engineering, manufacturing, and support to help you move faster—with confidence, clarity, and continuity.

Quality isn’t a step—it’s how we think, build, and deliver the future of healthcare.

Suneet Chadha, President, HiArc

Compliance built in from day one

Our concept development work is fully aligned with ISO 13485 standards and FDA expectations—ensuring your product meets the highest regulatory requirements from the start.

Expertise that meets you where your market is

From regulatory strategy to technical integration, HiArc brings cross-functional expertise that flexes to your team, goals, and stage of development.